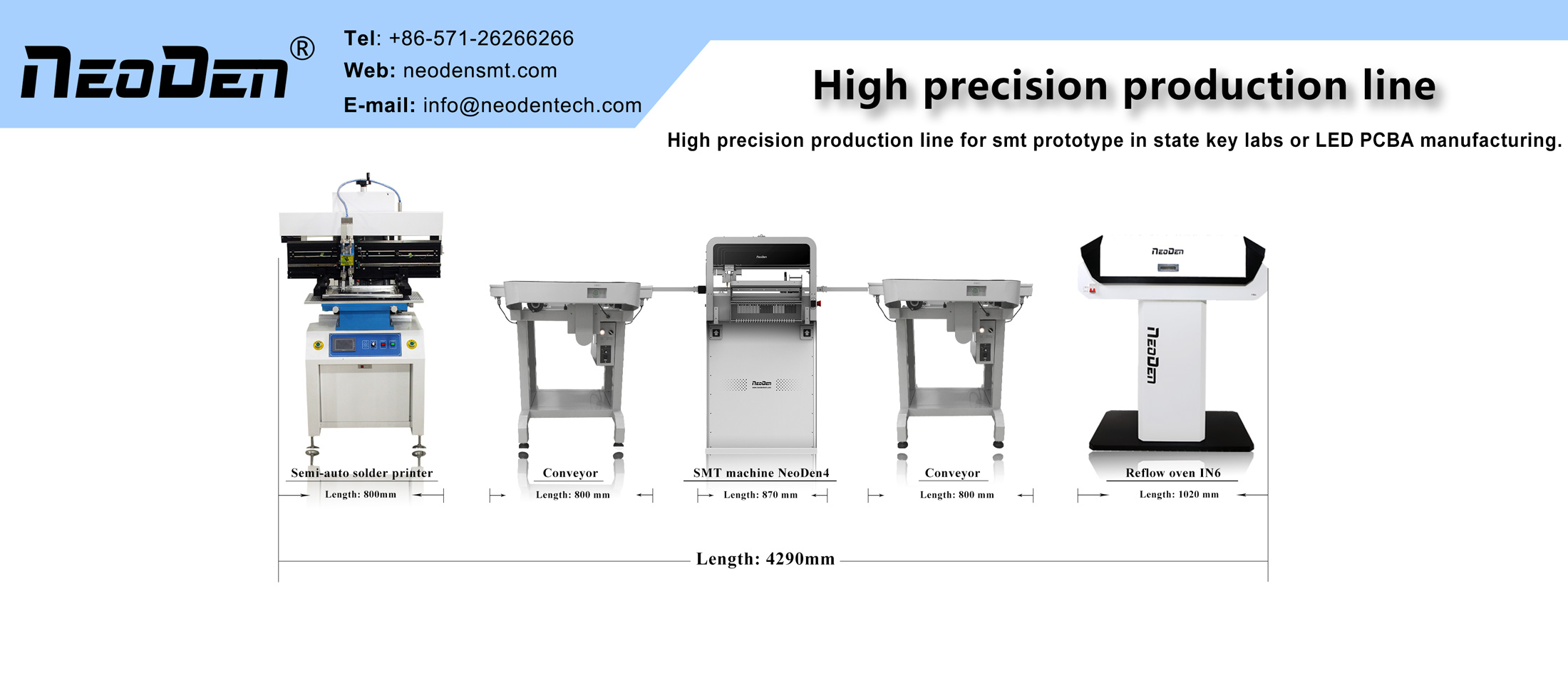

NeoDen High Precision Production Line

High precision production line for SMT prototype in state key labs or LED PCBA manufacturing.

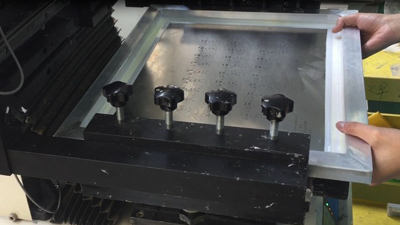

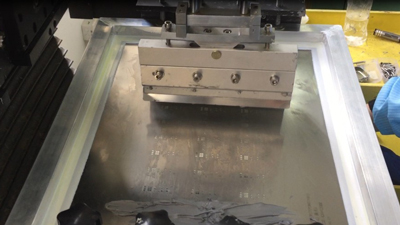

| Product Name | NeoDen YS350 Semi Automatic Solder Printer |

|

PCB size (Max) |

400*240mm |

|

Printing area |

500*320mm |

|

Frame size |

L 550-650 mm * W 370-470 mm |

|

Printing Accuracy |

±0.2mm |

|

PCB thickness |

0.2-2.0mm |

|

Air source |

4-6kg/c㎡ |

|

Power supply |

AC220V 50HZ / AC110V 60HZ |

|

Dimension |

L800*W700*H1700 mm |

|

Packing size |

1050*900*1850 mm |

|

Net weight |

230Kg |

|

Gross weight |

280Kg |

1. Control System

Microcomputer Control

Touch Screen Display

Menu User Interface

2. Touch Screen Interface

Time Display Function

Automatic Counting Function of Printing Times

3. Stencil

Similar to full automatic printing machine , the stencil will rise slowly within 2 seconds to demould then quickly rise to leave the PCB, which avoids the wire drawing occurring in the demould and saves time and improves production efficiency.

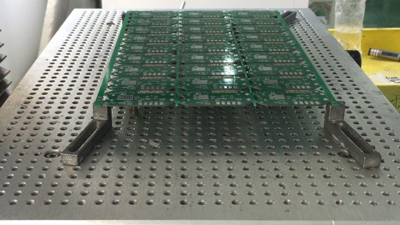

| Product Name | NeoDen 4 pick and place machine |

|

Nozzle Q'ty |

4 |

|

Reel Tape Feeder Q'ty(Max) |

48 (all 8mm) |

|

Max PCB size |

540*300mm (In Single Step) |

|

Max Placement Speed |

Vision on: 5,000CPH |

|

Vision off: 10,000CPH (Optimum) |

|

|

Voltage |

220V/50HZ & 110V/60HZ |

|

Smallest Component Size |

0201 (Electric Feeder Available) |

|

Largest Size |

32x32mm (Lead Pitch 0.5mm) |

|

Machine Dimensions |

870 x 680 x480 mm |

|

Net Weight |

60Kg |

|

Gross Weight |

80Kg |

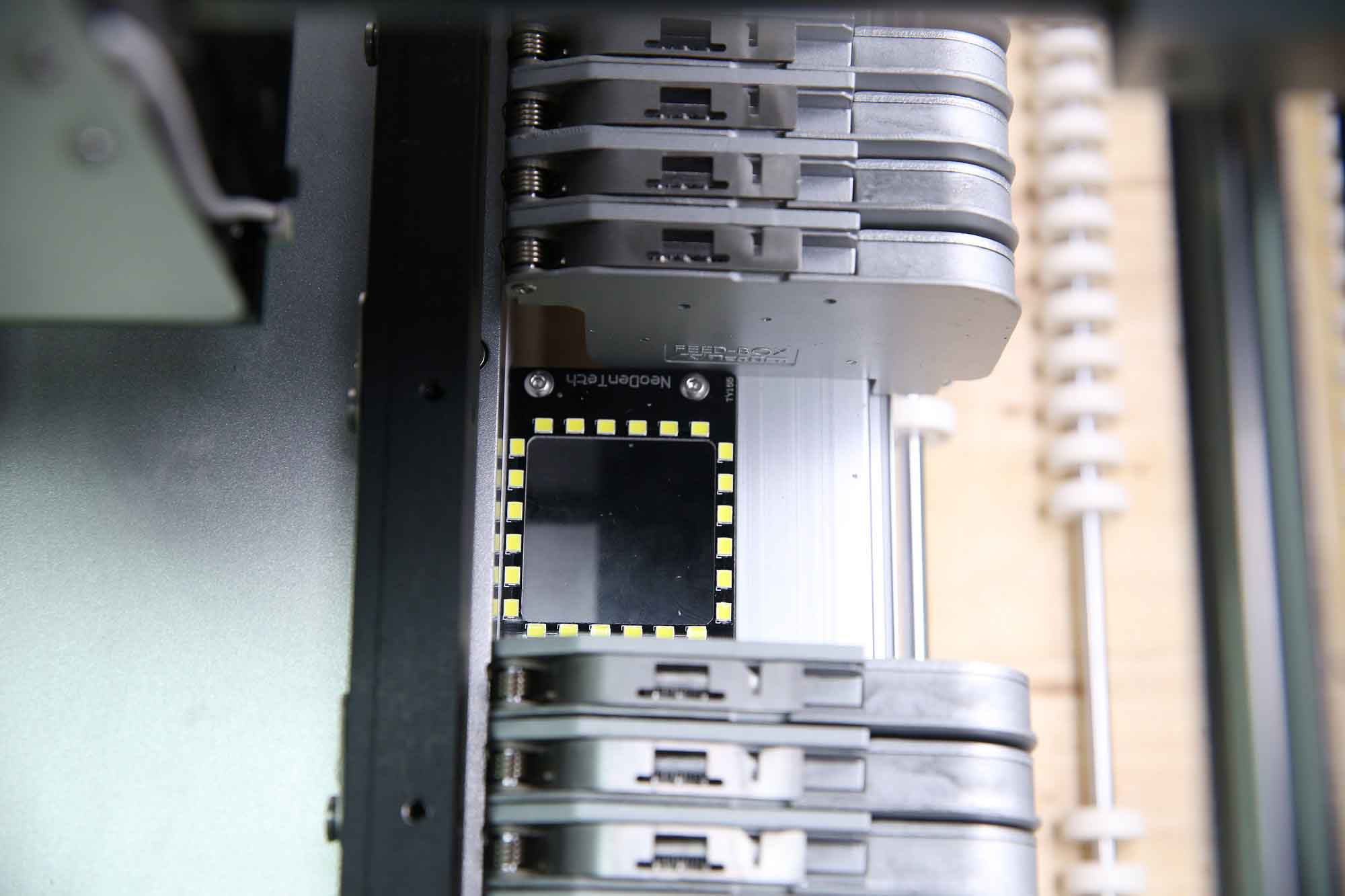

1. Vision system

An up-looking camera and a down-looking camera identifies and calibrates the different components simultaneously, and tremendously improves the accuracy of placement from 0201 to BGA.

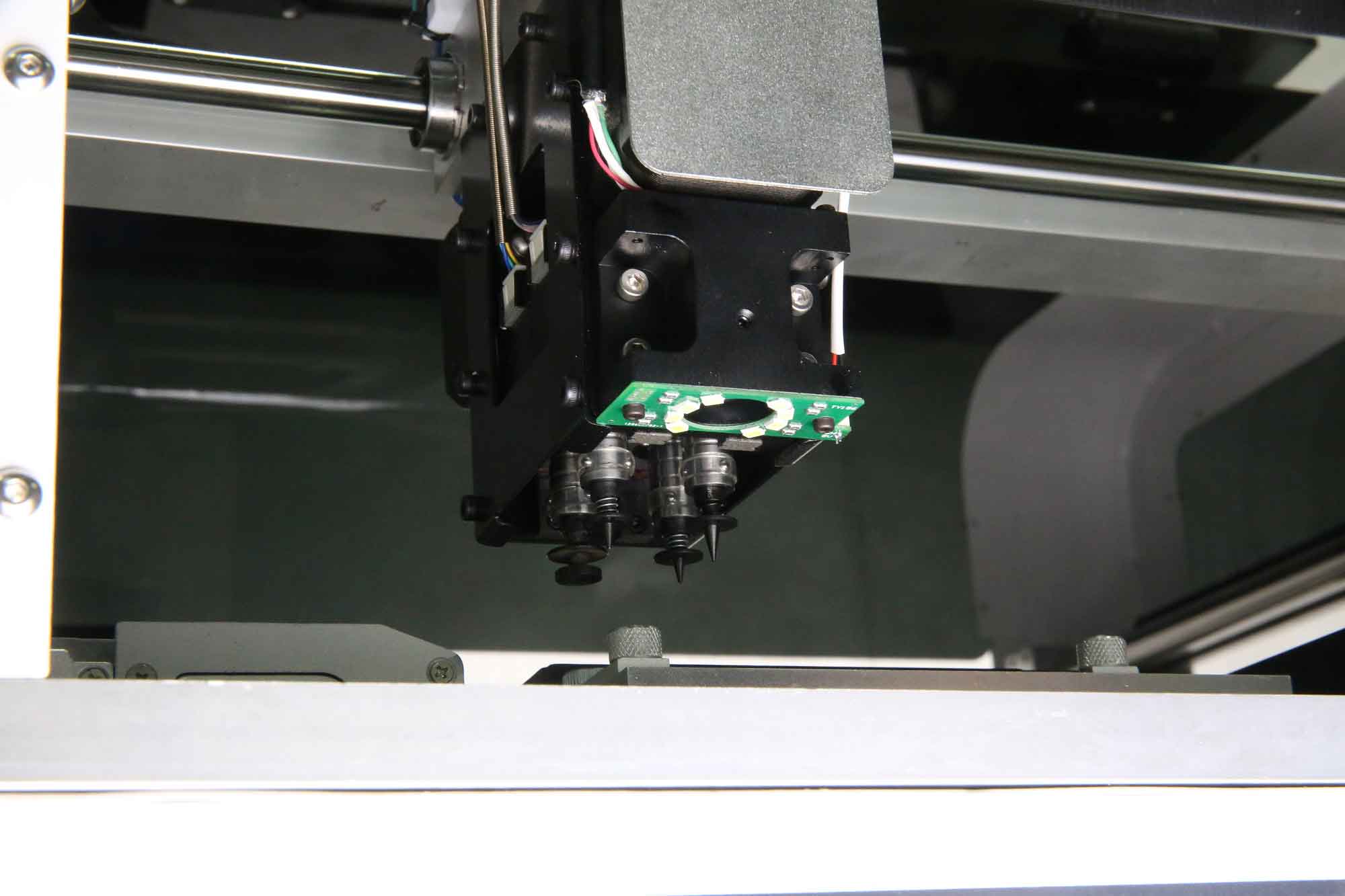

2. Four precision heads

4 high-precision placement heads with ±180° rotation that adopts suspended, fully symmetric and high degree

of coupling way, to ensure it can mount components with higher space, more gentle and more accurate.

3. Auto Electronic Feeders

Adopts feeding error corrections technique to help smooth the picking and reduce the deviation.

4. Auto Rails Achieve Continuous Placement

1.5m auto rails could be connected with universal conveyors to achieve continuous placement.

| Product Name | NeoDen IN6 Reflow Oven |

|

Heating Zone Quantity |

upper3/down3 |

|

Conveyor Speed |

5 - 30 cm/min (2 - 12 inch/min) |

|

Temperature Range |

Room temperature~300℃ |

|

Temperature Control Accuracy |

±0.2 degree celsius |

|

Temperature distribution deviation |

±1 degree celsius |

|

Max Soldering Width (PCB Width) |

260 mm (10 inch) |

|

Length Process Chamber |

680 mm (26.8 inch) |

|

Heat-up Time |

25 min |

|

Machine Size |

L1020mm×W507mm×H350mm |

|

Net Weight |

49KGS |

Detail

1. Full convection, excellent soldering performance.

2. 6 zones design, light and compact.

3. Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃.

4. Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high efficient, and transverse temperature difference is less than 2℃.

5. Original built-in soldering smoke filtering system, elegant appearance and eco-friendly.

|

Power supply |

Single Phase 220V 50/60HZ 100W |

|

|

Conveyor Length |

80 cm |

|

|

Conveying Belt |

ESD belt |

|

|

Conveying speed |

0.5 to 400mm/min |

|

|

Specification |

|

|

|

|

|

|

|

Packing Size |

880*720*310mm |

|

|

PCB available width |

30-300mm |

|

|

PCB available length |

50-320mm |

|

|

G.W. |

49kg |

|

Features

1. Precise adjustment of width

2. Smooth running, PCB won`t be stuck.

3. Speed adjustable